News

Discover our premium shipyard technology

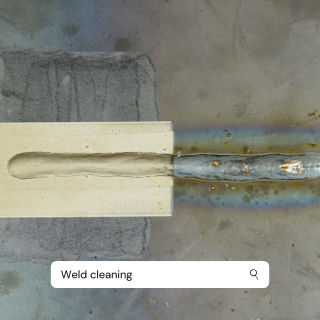

The shipping sector is under increasing pressure to build faster, cleaner, and smarter. Laser cleaning technology is emerging as a crucial solution,not just for surface preparation but for workflow efficiency, quality assurance, and safer working conditions. 1. Construction of Complex Naval Structures. Shipyards handle a wide mix of operations on partially finished vessels: welding, rectifying steel surfaces, installing cables and pipelines… and often returning to areas that require reworking. Traditionally, removing paint or coatings to access bare metal involves: Sandblasting (difficult in semi-finished environments) . Grinding . Pneumatic chiseling . These are invasive, messy, and time-consuming, and they require containment setups to protect surrounding zones. With a portable laser unit, the process becomes significantly more efficient: Work can be done precisely on small corners and complex surfaces . Surrounding areas remain untouched, no collateral damage . No need for local tenting or containment construction . Perfect adhesion readiness for re-coating . Fast, clean, silent, and safe operation . You can work just 10 cm from sensitive zones without barriers or shielding tools, saving you hours of preparation and rework. The result? Time reduction, lower indirect costs, and predictable planning. 2. Maintenance Operations at Sea. Why wait for dry-dock overhauls? A portable onboard laser system allows crews to: Clean stainless steel components affected by acid rain and corrosion . Remove rust spots before they spread . Maintain filters and mechanical parts . Perform targeted cleaning while the ship remains operational . This makes maintenance preventive instead of corrective, reducing future downtime and extending component lifetime. 3. Proven Worldwide, Trusted by Industry Leaders. With rising preparation standards and shorter construction cycles, major shipbuilders are turning to pulsed laser cleaning. P-Laser delivered its first high-power system to Samsung Heavy Industries (South Korea) in 2019, Keppel 2020 , starting a long-term collaboration and deep technical insight into shipbuilding needs. P-laser technologies produces it's own electronics and optical path systems handeling the highest puls energies today availeble in the world. This equipment has to indure the toughest environment in shipyards from Korea to Alaska and Canada. Fiber lenghts till 100 m are standard technology for us. Today, shipyards around the globe rely on us to: - Improve paint adhesion on welds and hard-to-access areas- Eliminate messy sandblasting and post-cleaning work- Avoid production delays caused by surface rework- Upgrade working ergonomics and reduce contamination exposure Laser cleaning is no longer an alternative technology, it’s a quality accelerator and a productivity tool. Ready to future-proof your shipyard operations? Let’s discuss how pulsed laser cleaning can streamline your construction and maintenance workflows.

Automatic tire mould pulsed laser cleaning solution

The tyre sector has to gear up seen the difficult automotive situation. Fast start/stop systems are key to have a flexible production system.P-laser is always thinking with our customers to reach the maximum effective solution.Integrating our German pulsed made fiber laser sources is giving our customers a trouble free production run for severall year. Our in the cloud connected systems can be looked at in remote status over the world. Tyre molds are very sensitive to sticking if not proper cleaned with the right laser system. Please contact us for more information.

AMPP recognises pulsed laser cleaning as alternative technology.

The adoption of pulsed laser cleaning by the Association for Materials Protection and Performance (AMPP) as a recognized alternative technology in industrial surface preparation is a significant development. This recognition underscores the growing importance of innovative and sustainable solutions for surface preparation in industries such as oil and gas, automotive, aerospace, and infrastructure. Pulsed laser cleaning offers several advantages over traditional methods like abrasive blasting, chemical cleaning, and mechanical processes. Key benefits include: Precision Cleaning: Pulsed lasers can remove coatings, rust, or contaminants with high precision, without damaging the underlying substrate.. Eco-Friendly: It eliminates the need for abrasive materials and chemicals, reducing environmental impact and waste disposal requirements.. Non-Contact Method: The process minimizes mechanical wear or distortion, making it ideal for delicate or intricate components.. Reduced Downtime: Faster cleaning processes can translate into reduced downtime for industrial operations.. Safety Improvements: It reduces exposure to hazardous chemicals and airborne particulates for workers.. AMPP's recognition suggests that pulsed laser cleaning has reached a level of reliability, efficiency, and practicality suitable for widespread industrial use. It also signals a shift toward embracing cleaner and more sustainable technologies in materials protection and performance.

We're taking over the air.

03/09/2018

After entering the US-market, our P-Laser USA team got immediate response of some leading aeronautic companies. After some successful demonstrations, they ordered some of our Low Power systems. If you want to try our laser yourself, contact us. The sky is the limit!

Anode cleaning with lasers

22/01/2021

AiRC-1000: cleaning anode rods. P-Laser proudly presents the AiRC-1000; the new industry standard for cleaning anode rods by our Australian partner Automation Innovation Pty Ltd Energy-efficient cleaning. Aluminium smelters are looking to reduce energy costs and improve efficiencies which the AiRC-1000 delivers. The use of new laser technology replaces the old and inefficient methods of cleaning anode rods, providing optimum rod surface conductivity that lowers electricity usage during the smelting process. Fast return on investment. The estimated return on investment for the AiRC-1000 is between 12 to 18 months for an average-sized plant. Check out the video.

Laser cleaning of Aluminium surfaces prior to welding and post laser cleaning process.

26/07/2022

In today's industry, Aluminium (Al) is one of the most commonly used nonferrous materials after ferrous grades of steel and stainless steel.

Case: Restoration of an old Cottage

26/10/2020

Laser cleaning can be used to conserve and restore important works of art, architecture, and cultural heritage. In this case laser cleaning has been used to restore parts of an old stone cottage and its artefacts in a remote area of South West Ireland. Cause of a fire damage. The cottage had no foundations, which was common at the time of building, with walls 2 feet thick, made of large stones. Due to a violent fire inside the cottage, a considerable internal damage has been caused by the black acrid smoke that travelled to all parts of the house. Work began on restoring the cottage to itsoriginal state. Laser cleaning of the cottage. The battens in the house were a cause for concern. Only one of them was burned but the rest were coated in a sooty residue. Should all the battens need replacing, the upstairs floor, which was attached to the battens, would have to come down too. The cost for doing this would be quite considerable. In order to avoid this, laser cleaning was employed and was able to remove the soot, both from the painted battens and the plaster board. During the cleaning process they used the P-Laser Compact QFC-100 hand-held portable fibre laser at full power, with a programmable line width of 200 mm and adjusted the focal length to the maximum of 500 mm. Download the complete article about this restoration here.

AiMC-1000: The new industry standard for cleaning glass moulds

01/10/2020

P-Laser presents the new industry standard for cleaning glass moulds. Glass mould cleaning made greener, safer and more efficient. The AiMC-1000 was developed by Automation Innovation and uses our 1000 watt high power laser to clean the surface, ensuring that only the contaminant is removed with no damage to the parent mould material. The state of the art 3D-scanning technology (Siemens) allows the machine to clean any type of mould with extreme precision. In collaboration with our Australian partner Automation Innovation. Watch the video here.

New: QF-Arol

21/09/2020

The QF-Arol is a magnetic robot, which allows you to clean metal structures vertically. Laser cleaning can now be used in even more applications. The QF-Arol in the storage and steel business. The QF-Arol solution will mainly target the business of large storage silos and large steel surfaces. The robot can for example clean the welding strip of the silos before performing the quality control of the weld. The QF-Arol for eco-friendly decoating and rust removal. Other applications are decoating or rust removal. This eco-friendly solution avoids the use of a high quantity of pressurized water or is replacing the traditional cleaning methods consuming high amounts of electrical energy. Watch the video here.

P-Laser on Business Insider website

02/07/2020

Tech Insider. In collaboration with P-Laser, Tech Insider published an article about laser cleaning. It explains the working principle very well, and shows some nice P-Laser clips. Check out the video here.

P-Laser for rubber and plastic

29/04/2020

Different industries. Laser cleaning can be used in many different industries. Discover the applications in the rubber and plastic industry in this article (in Dutch). Kunststof & Rubber. The article was published in Kunststof & Rubber magazine. Read it here.

Sustainable plastic mould cleaning

21/01/2020

LaserClean, our Canadian service partner, uploaded a great video of them cleaning plastic moulds with our laser. Check out the video.