Laser cleaning of Aluminium surfaces prior to welding and post laser cleaning process.

26/07/2022

In today's industry, Aluminium (Al) is one of the most commonly used nonferrous materials after ferrous grades of steel and stainless steel.

26/07/2022

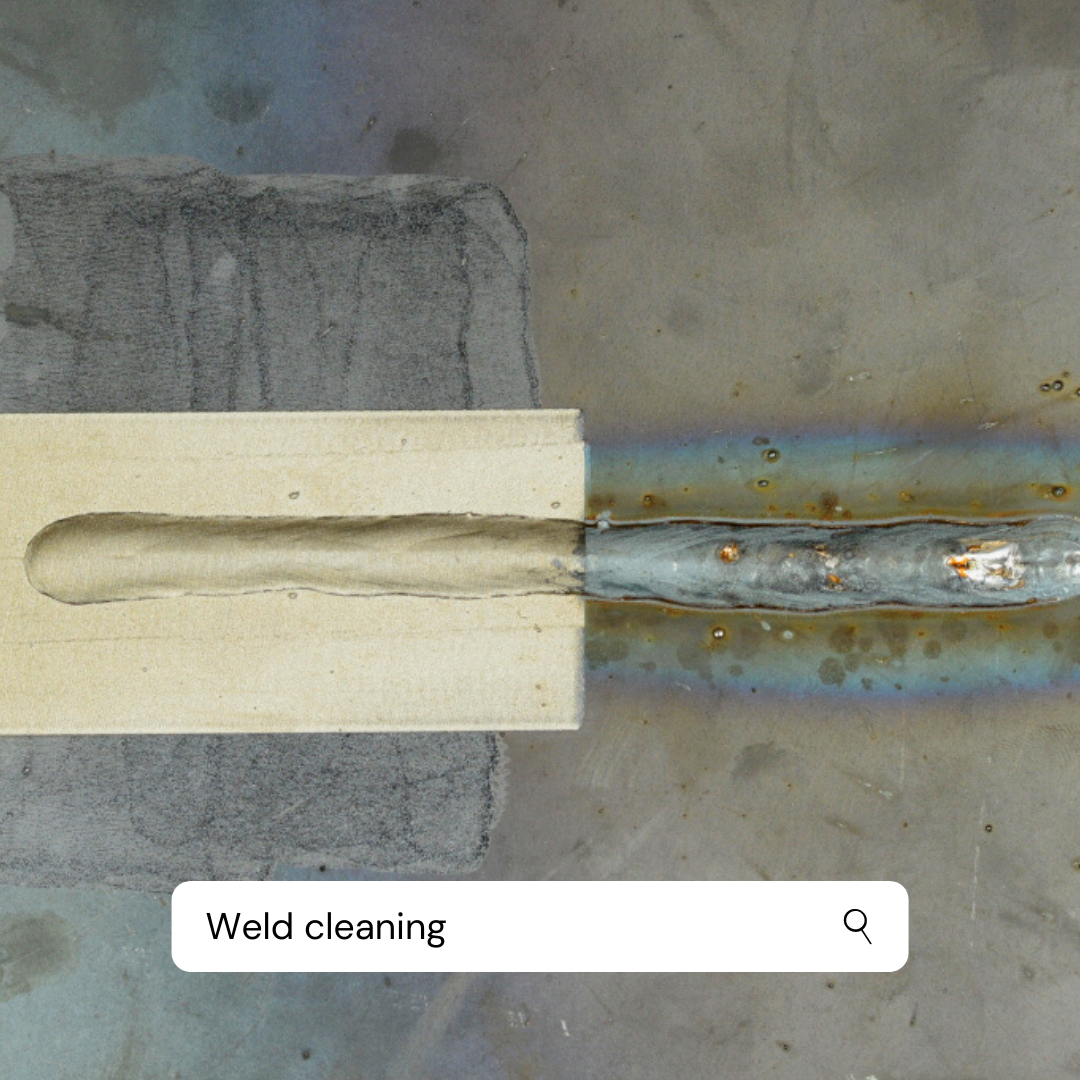

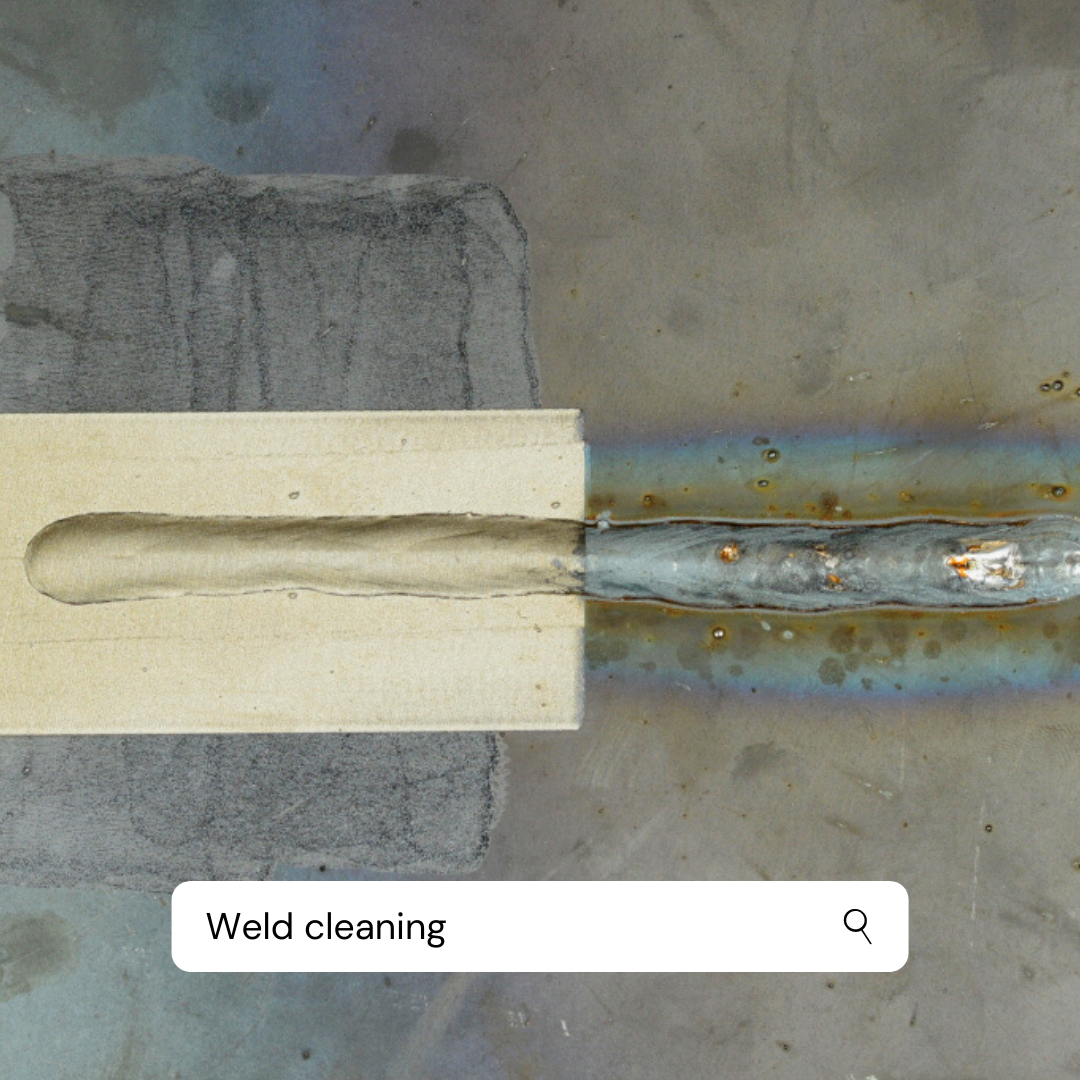

weld cleaning

Metal inert gas welding (MIG), tungsten inert gas welding (TIG), and laser welding (LW) are the most commonly used methods for welding aluminum materials. The success of aluminum welding is determined by the resistance of the weld metal to the cracks, especially solidification cracks, and the porosity in the weld. If these are not observed in a certain group of aluminum welds, we can consider the weldability acceptable. On the other hand, the weldability is influenced by the welding process, the effect on the aluminum base material and the surface conditions, chemical composition and mechanical properties before welding, welding parameters, shielding gas, and filler wire. If the aluminum oxide on the surface is not cleaned, it will act as cores for gas pores during welding. The oxides on the surface also contain dust, lubricant, and hydrogen (H2) from surface oxide film, lubricant on the aluminum welding wire, and the purity level of the shielding gas. Argon or Helium is never 100% pure and may contain other unwanted gases and contaminants. Low temperature (eutectic) melting elements in the aluminum such as Mg, Zn, Mn, Si, etc. during welding can form gas porosities. These low-temperature fusing elements (Mg, Zn, Mn, Si, ...) cause hot cracks in the welds, which are typical disadvantages of aluminum welds.

This website uses functional cookies that are minimally required to make the website work properly. There are also additional cookies. They are completely anonymous and map your usage for analysis and research purposes.

Click here for our privacy and cookie policyOptimise ads based on your browsing behaviour and ensure optimal interaction with social media such as Youtube, Twitter, Facebook or Instagram.