CUSTOM-MADE PROJECTS

laser cleaning, optimised for different applications!

Tagline

Customer demand

We specialize in producing advanced laser equipment tailored for various sectors, including nuclear, shipbuilding, food processing, and welding.

Working closely with our customers, we ensure their specific requirements are met, delivering optimal solutions for laser cleaning tasks.Inline steelplate cleaning, magnetic robots for weld cleaning prior to NDT inspection, till class 1

laser hand tools.

Arol 4x4

The QF-Arol is a 4 wheel magnetic robot, which allows you to clean metal structures vertically. Laser cleaning can now be used in even more applications (patent pending).

Arol 2 (new)

This new 2 wheel Segway type magnetic robot is even more maneuverable in corners and inside tanks and ship hulls. They can be used with our standard high power lasers.

Class 1 Optic

In some cases, there can be no visible laser light during cleaning, so our R&D department developed this optic system, making it safe to operate without laser goggles! Patent pending.

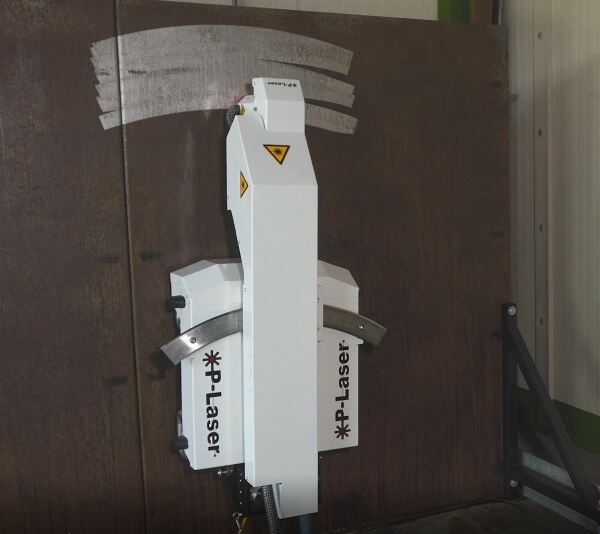

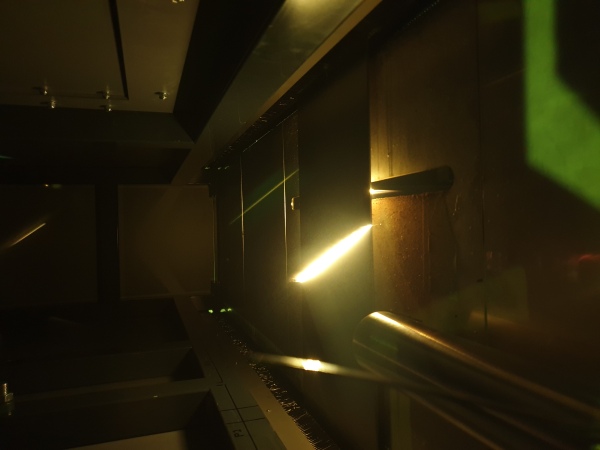

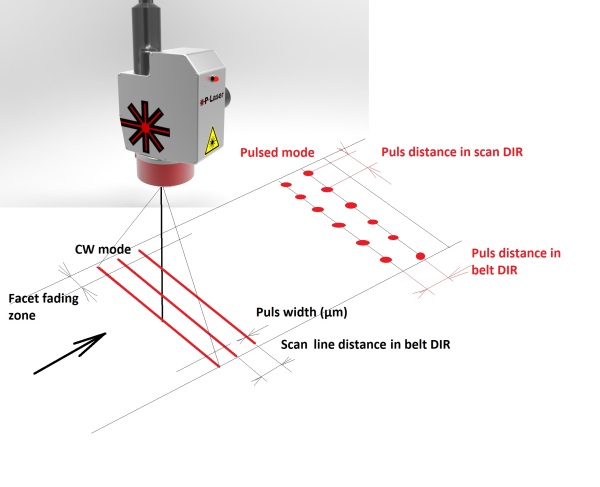

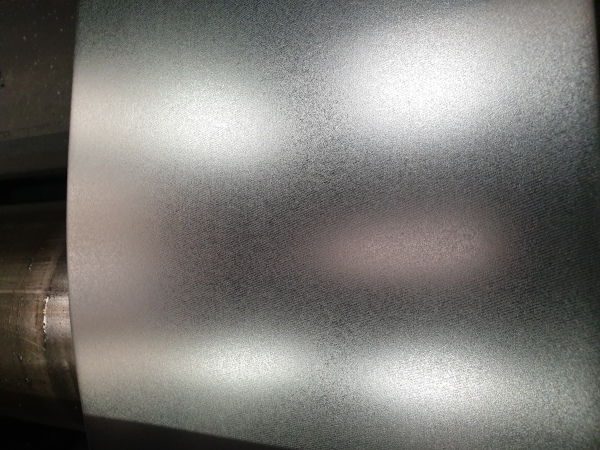

High Speed polygone scanner with CW 5Kw laser

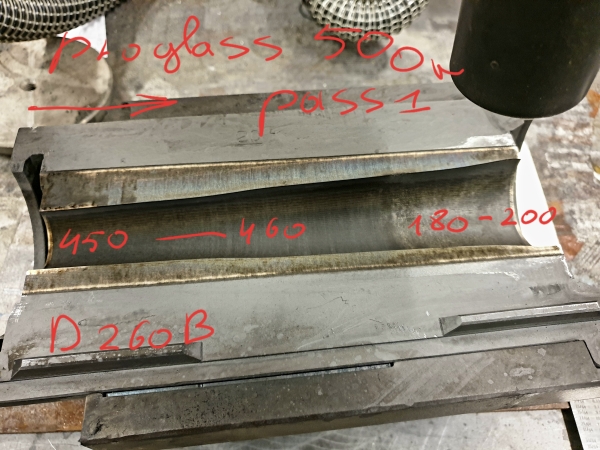

P-laser developed high-speed scanner for CW and Pulsed laser sources. If you need to clean high-speed sheet metal, a standard optical scanner cannot generate enough surface speed to have a full surface coverage. The polygon scanner consists of a high-speed rotating multi-facet mirror. We can reach surface speeds till 600 m/s instead of max 30m/s with conventional mirror x-y scanner.At the left side you see a test rig with 2 polygone scanners which can operate till 5KW watt to clean a moving belt at 60m/min.

see below ; left pic 1: view on top side cleaning ; pic2: polygone scanner path; pic3: plate before cleaning; pic4: after cleaning.

Tagline

Inline quality control system

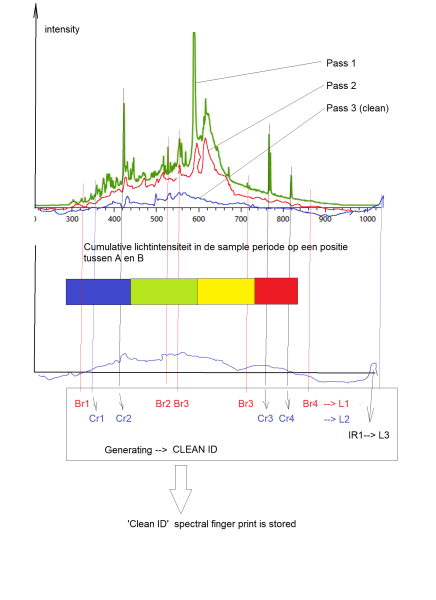

P-laser developed an inline spectral monitor system ( patent pending) to monitor the cleaning progress. Industrial applications demand inline monitoring of changes in the base material and the cleaning quality. The used laser is shooting infra red laser pulses to the surface. The present surface contamination will react by being oxidized by the infra red radiation. the transition from the surface contamination will be visible and can be detected by a spectral sensor.Depending on we will get a spectral snap shot in reference to the surface state ( reflection, absorption) . By making a reference spectral fingerprint of your desired surface state the laser system can in an automatic mode clean the surface till the required quality is reached. This auto-self-regulating system cuts slack time when your input material has variations in contamination and even unwanted substances like Chromium, lead or Zinc particles

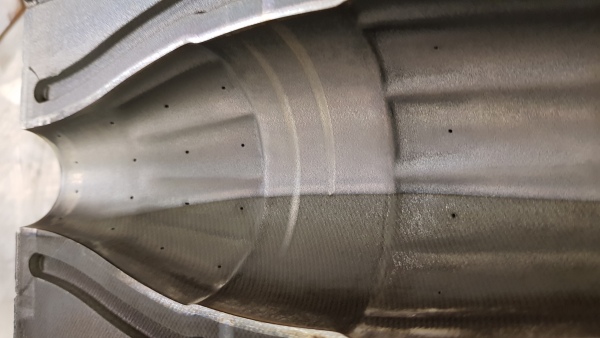

Left we have an example ( glass mold) where the contamination is always different depending on the production cycle. On a daily basis, hundreds of glass molds must be cleaned.You could program every mold to be cleaned in a fixed time delay off 45 seconds, but some only require 30 seconds. This slack-time optimisation with our spectral sensor will reduce your cleaning time.

Left we have a spectral line print for every pass over the glass mold. The green one is the first cleaning pass, the blue one is the last. The contamination present on the mold surface is oxidized by the laser radiation and sends light back captured by the sensor. After every cleaning pass the contamination is reduced as the quantity of light. With the right algorithm, you can determine your required cleaning level and have a automatic machine learning process.